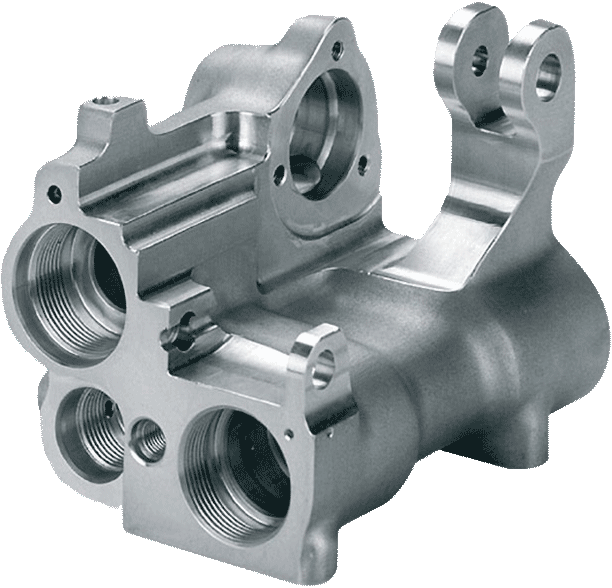

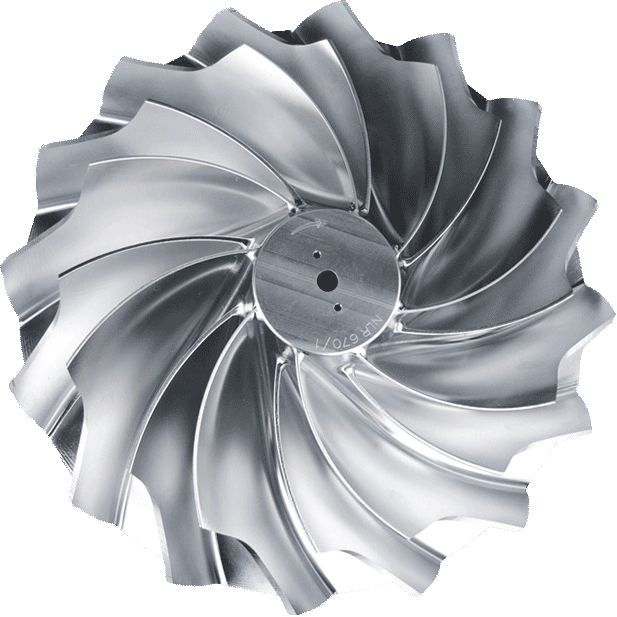

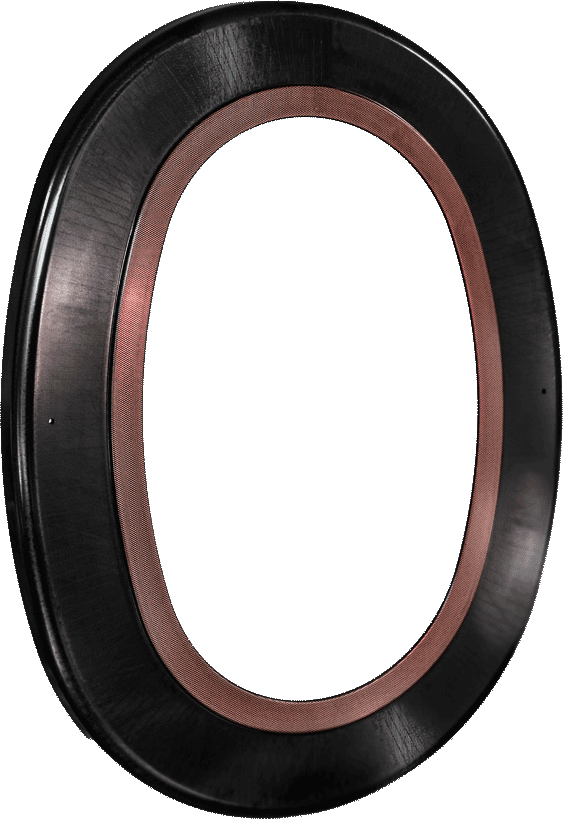

At our locations in Bermatingen (approx. 120 employees) and Markdorf (approx. 50 employees), we manufacture precision components and assemblies for the aerospace and mechanical engineering industries using state-of-the-art technology.

Our commitment: highest quality, maximum reliability, and technological excellence — from single parts to complex assemblies. We are a hidden champion in precision parts manufacturing.